Augmented Reality in the Automotive Industry

Drive Innovation and Efficiency with Immersive Technology

The Impact of AR on the Automotive Industry

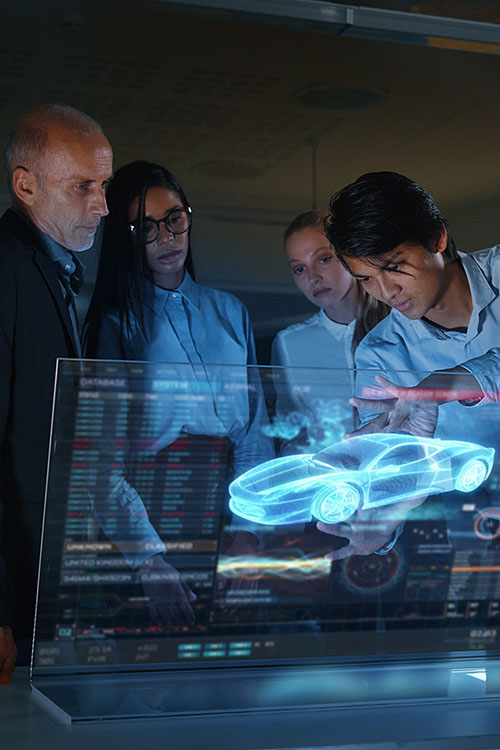

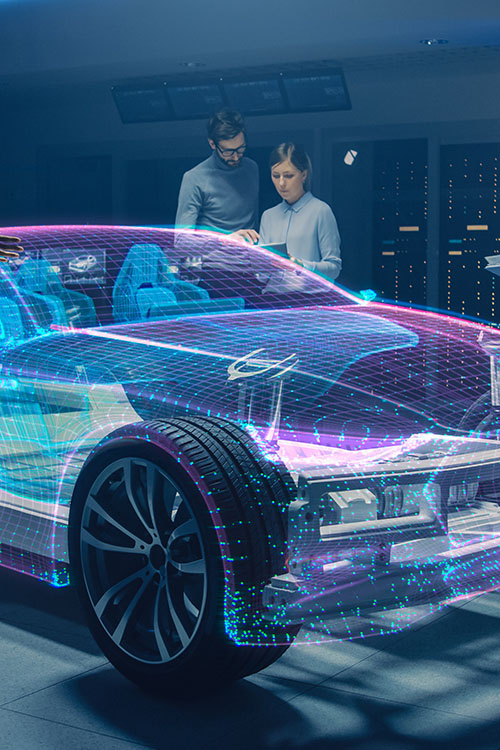

Cars are a unique blend of advanced technology and consumer desires. Designing them presents specific challenges, including attention to detail, global collaboration, and the risk of costly mistakes. The whole process is inherently visual – so why not optimize it by making it an immersive experience? Augmented Reality revolutionizes innovation, design, and manufacturing by enabling everyone in the workflow to visualize complex designs in 3D. The result is faster and more accurate prototyping, improved collaboration, as well as reduced errors and costs.

AR Use Cases in Automotive Manufacturing

Product

Development

Stakeholder

Engagement

Assembly

Training

Quality

Control

Design

Reviews

Streamlining Design Processes and Reducing Costs

AR simplifies prototyping and accelerates innovation by allowing automotive engineers and designers to experience data in a 3D context. They can visualize prototypes and designs as full-scale 3D holograms, take them apart, review them and make changes: A much more tangible, real-world way to work and collaborate around engineering data and decisions. As a result, immersive AR helps identify and prevent design errors early in the process, minimizing the number of iterations and prototypes required. This not only saves time, but also reduces costs and errors in production.

Streaming for Enhanced Productivity and Security

For the automotive industry to take full advantage of immersive AR, it is important that it can be used on mobile devices such as XR headsets or smart glasses. In addition, content should be based on existing data and available in its original complexity, size, and quality. By streaming applications, all data can be hosted on high performance external servers, allowing for a seamless 3D data pipeline without the need for data simplification. What’s more, the data is subject to centrally managed security measures, reducing the risk of theft or unauthorized access.

Leading the Industry into the Industrial Metaverse

Boosting Training Experiences and Reducing Downtime

By using Augmented Reality for training, companies can reduce product losses, simulator costs, and travel expenses. Immersive AR allows operators to train on virtual production lines or prototypes without shutting down production or building expensive simulators or physical replicas. AR also reduces the risk of injury and exposure to hazardous materials. What’s more, using Augmented Reality for training adds interest and reduces constraints, making training more appealing, flexible, and cost-effective.

“At Hololight, we focus on improving essential elements within the “cradle to grave” span of the automotive industry. We try to anticipate which key parts of the value chain can be positively impacted or changed by Augmented Reality to contribute to higher profitability for an OEM and its supply chain partners. Engineering, production, quality assurance, all have enormous potential for improvement.“